Our technology

RGS patented production process

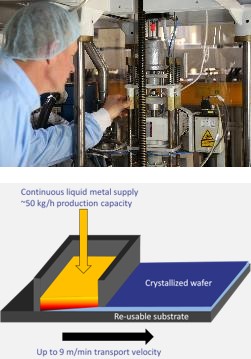

The abbreviation “RGS” stands for Ribbon Growth on Substrate. It’s a unique “rapid casting” production process for advanced semi-conductor based alloys.

This RGS process is based on fast direct solidification of wafers out of a melt with well controlled material composition. The process is conducted in a fully enclosed high temperature low pressure atmosphere

The characteristics of this process are:

- Full utilization of often expensive feedstock materials

- Continuous high speed production process

- Homogeneous material composition and quality over total production run

- Fully automated and accurate process control

- Very fast solidification enabling nano sized structuring of material

RGS Development uses its material know-how in combination with this unique and patented casting process to manufacture nano-structured silicon alloys that are engineered to different applications.

Due to the characteristics of the patented RGS production process, silicon alloy materials can be produced extremely cost efficient and with well controlled quality specifications