CHP - The Thermagy products

The Thermagy heat panel and Thermagy heat module are the first configurations of the Thermagy concept. This basic configuration is based upon a flat panel shape with radiation as the hot side heat source and water cooling as the cold side heat sink.

The Thermagy poducts (panels, modules and test-probes) work stand-alone but can also be used to:

- work in combination with an ORC (Organic Ranking Cycle) installation that typically harvests lower temperature heat

- autonomously power sensors in a high heat environment

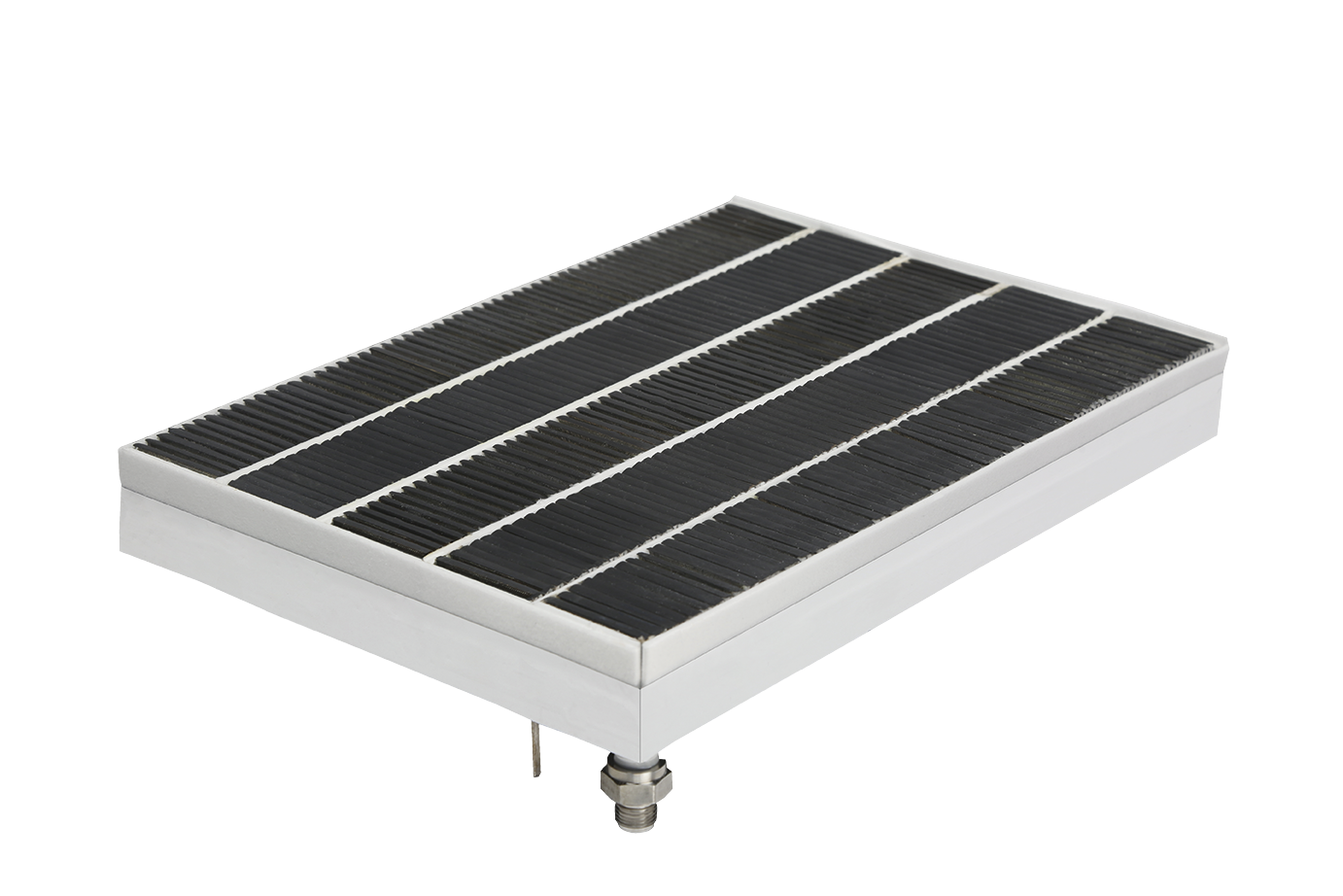

Thermagy heat panel

A Thermagy heat panel is a 200x300 mm Thermo Electric Generator device (TEG), to be positioned above and exposed to a radiation heat source. A Thermagy heat panel is equipped with integrated water cooling and electrical connections. A Thermagy system is built by putting heat panels in an array according to the required system geometry. Once mounted the panels have to be connected to the electrical and water/steam infrastructure. At system level, an electrical inverter can be added to convert DC to AC.

For the Thermagy panel specification download the datasheet

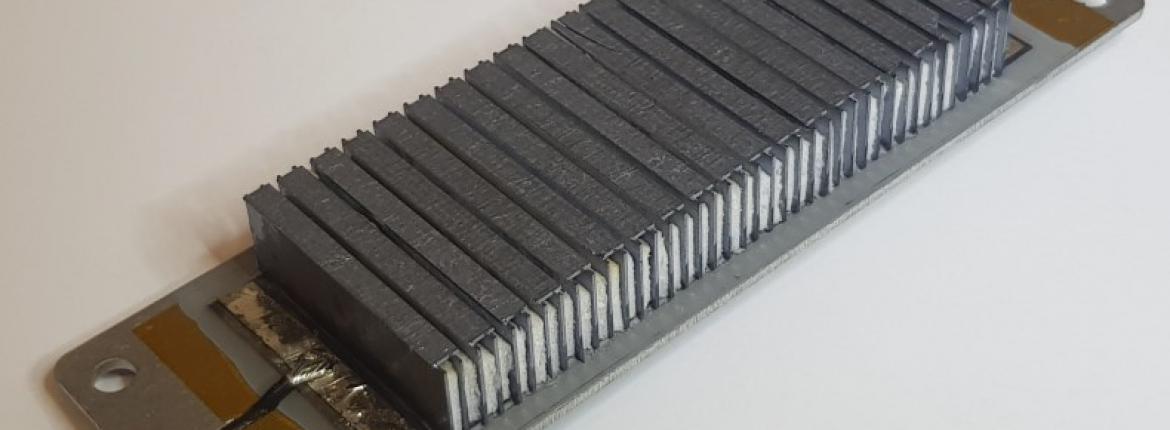

Thermagy heat module

The Thermagy heat module is the 100x40mm building block for the Thermagy heat panel, however suitable for small surface applications or testing purposes. Think of powering sensors to measure high heat processes or application in test-probes as described below.

Integrable Thermagy unit

RGS offers a fully equipped hexagon Thermagy unit to merge with circulair heat sources (surface temperature 700°C and above). This Thermagy unit can be used to generate electricity and capture heat in coolants for user purposes.

Thermagy hexagon pipe

With our heat panel technology, we recently put together a hexagon pipe to capture heat and generate electricity from burners, exhausts and heat pipes.

The hexagon pipe can be designed and manufactured in various diameters. The round, hot and radiating sources heat up the integrated modules equally and give direclty electrical power to transfer heat by pumps or fans.